E-Mail

E-Mail

low cost and long service life. It is especially suitable for the anti noise use of elevated expressway, urban light rail and subway. It is the most ideal sound insulation and noise reduction facility in modern cities.

low cost and long service life. It is especially suitable for the anti noise use of elevated expressway, urban light rail and subway. It is the most ideal sound insulation and noise reduction facility in modern cities.

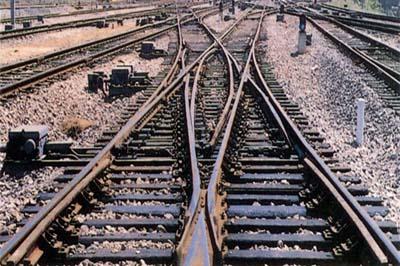

The main reason why these nuts are easy to loosen is the effect of external force. When the high-density traffic flows through the turnout, the huge vibration force will cause the nut to loosen. In addition, because the long angle steel of the installation device is not perpendicular to the base rail, the bolt connecting the angle iron and the rail waist is subjected to a transverse torque, which accelerates the loosening of the nut. After the test, the method of adding spring washer between double nuts is economical and affordable, and has achieved a certain anti loosening effect, but the anti loosening time is still not long enough and not ideal.

The main reason why these nuts are easy to loosen is the effect of external force. When the high-density traffic flows through the turnout, the huge vibration force will cause the nut to loosen. In addition, because the long angle steel of the installation device is not perpendicular to the base rail, the bolt connecting the angle iron and the rail waist is subjected to a transverse torque, which accelerates the loosening of the nut. After the test, the method of adding spring washer between double nuts is economical and affordable, and has achieved a certain anti loosening effect, but the anti loosening time is still not long enough and not ideal.

In the process of high-speed running, the train shall be able to withstand the strong vibration caused by external forces and natural factors, resulting in the continuous decline of the equipment performance of the train, which will inevitably lead to the deterioration of the equipment operation condition and even the damage of components, which will seriously endanger the driving safety. Therefore, the most important link of vehicle overhaul and maintenance, The premise of maintenance and overhaul is that the train shall be well fastened. In view of this situation, it is particularly important to choose a safe, reliable and durable fastening method. Most of the fasteners used in the traditional track system are ordinary nuts and bolts, and then chemical glue is added. However, the chemical glue is easy to age, and the anti loosening effect is greatly reduced after wind and rain. When this traditional fastener is applied to the catenary structure of high-speed railway and motor car, it is very harmful. The fast train speed drives the strong tension to impact the catenary, The anti loosening performance of fasteners is particularly important at this time. This requires that fasteners must have high tensile strength, good toughness and corrosion resistance. The material elements selected for bolts and nuts are directly related to the mechanical properties of fasteners. Therefore, fastener manufacturers are required to sample the materials for manufacturing bolts and nuts into test pieces, and test the mechanical and physical properties according to class A and class B items in GB / T 3098.1-2000. No matter which test is selected, it must meet all the requirements of GB / T 3098.1-2000, The mechanical properties of nuts shall meet all requirements specified in GB / T 3098.2-2000.

resulting in the continuous decline of the equipment performance of the train, which will inevitably lead to the deterioration of the equipment operation condition and even the damage of components, which will seriously endanger the driving safety. Therefore, the most important link of vehicle overhaul and maintenance, The premise of maintenance and overhaul is that the train shall be well fastened. In view of this situation, it is particularly important to choose a safe, reliable and durable fastening method. Most of the fasteners used in the traditional track system are ordinary nuts and bolts, and then chemical glue is added. However, the chemical glue is easy to age, and the anti loosening effect is greatly reduced after wind and rain. When this traditional fastener is applied to the catenary structure of high-speed railway and motor car, it is very harmful. The fast train speed drives the strong tension to impact the catenary, The anti loosening performance of fasteners is particularly important at this time. This requires that fasteners must have high tensile strength, good toughness and corrosion resistance. The material elements selected for bolts and nuts are directly related to the mechanical properties of fasteners. Therefore, fastener manufacturers are required to sample the materials for manufacturing bolts and nuts into test pieces, and test the mechanical and physical properties according to class A and class B items in GB / T 3098.1-2000. No matter which test is selected, it must meet all the requirements of GB / T 3098.1-2000, The mechanical properties of nuts shall meet all requirements specified in GB / T 3098.2-2000.